Our Factory

The Technical Art of Crafting Sensation

We present a full range of integrated jewelry solutions by investing in mines and operating our own factories. Our factories in Lufeng and Panyu support the demands of the Fai Po Gem & Jewellery Ltd. company with precision, quality, and excellence.

Stone Cutting Process

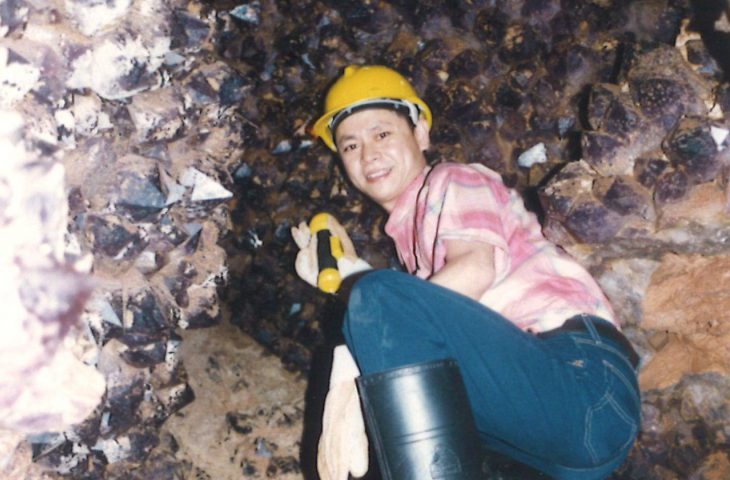

Mining

The gemstone sources are where the precedence for high-quality jewelry is set. That is why we personally visit our mines in southern Africa, South America, and Asia to evaluate their exemplary standards of quality, sustainability, and range. Our sources ensure our gemstones are from conflict-free zones, with each striving to impact the local communities they are located in positively.

Processing

We use mechanized equipment for efficient gemstone processing at mines, including high-pressure water jets to wash gemstone-bearing rocks, high-end sorting systems to screen gemstones, and precision selection systems to identify the finest gems.

Enhancement

Before the jewelry-making process begins, gemstones are enhanced. First, diamond saw blades cut gemstones to the desired thickness. Then, they are ground with coated disks and wheels and sanded with sand-bonded cloth, paper, and belts. Finally, polishing with leather and hard felt results in a mirror-like finish and radiant shine.

Jewelry-making Process

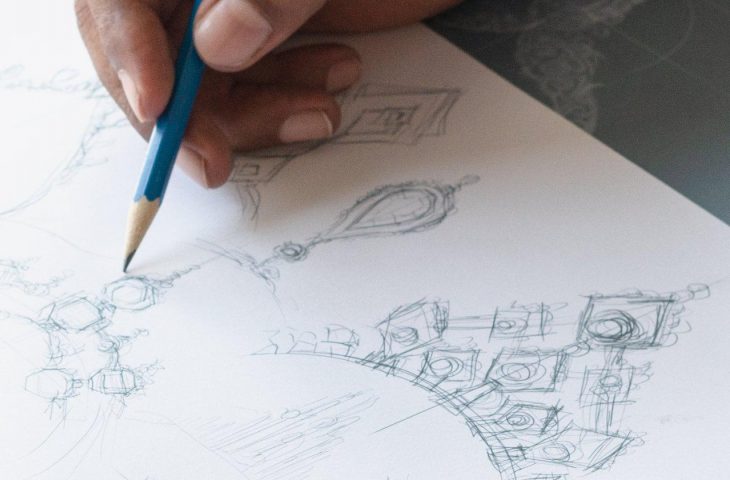

Design

The design process always begins with sketching. Once a concept is put on paper, we begin pre-production by working closely with our production facilities to conduct a few rounds of prototype and revision.

Modeling

After the final revision has been made, we create 3D/CAD models for approval and, once approved, we compile the drawing and the model for the jewelry master craftsman. When a design is chosen, it will undergo countless minute but important adjustments until the design is finalized.

Rubber Model Cutting

We create a rubber mold around the model made by the jewelry master craftsman called the master, and vulcanize it, hardening the rubber into a more durable material. The identical hollow impression remains when the master is removed from the mold after vulcanization. Rubber molds can be reused up to 2,000 times.

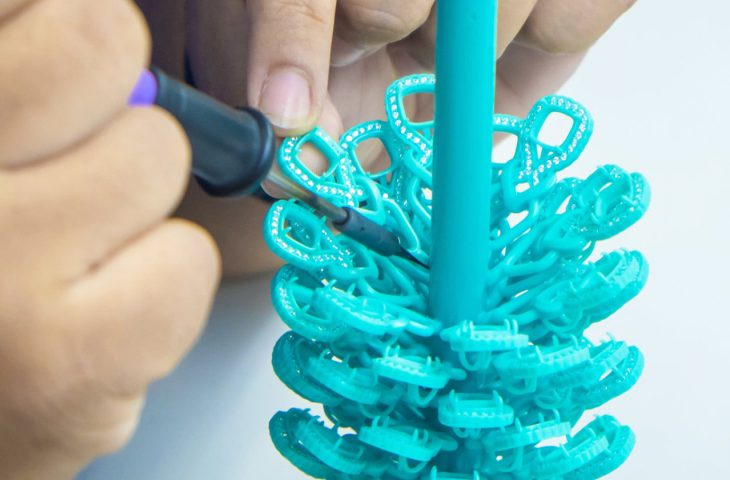

Wax Model and Treeing

Molten wax is injected into the rubber molds and compressed with metal plates to prevent wax seepage. After the wax hardens, we remove exact copies of the master from the molds. The wax models are made into wax trees and used to make plaster molds.

Casting

The plaster molds go into a casting machine and silver or gold alloy is poured in, resulting in forms that are exact matches of the master.

Assembly & Setting

Our skilled goldsmiths use a wide range of crafting techniques to adorn, assemble and solder each design with different elements. After fitting clasps, soldering bails, and adding metal cores and silicone grips, stones are set in classic and contemporary settings.

Polishing and Finishing

Once the plaster casts have cooled, the metal jewelry is cut off metal trees and refined through grinding. After expert goldsmiths assemble and solder the design with clasps, bails, charms, and glass cores, the piece's surface is smoothed and brought to a final shine in various treatments: high shine, satin, matte and other textures.

Plating

Plating gives special finishes to select high-quality metals to create different color tones by covering a conductive jewelry surface with metal. This step inhibits corrosion, improves wearability, reduces friction and many other purposes.

Quality Control

While quality control measures are taken throughout the production and manufacturing process, the final quality control assesses all jewelry pieces through a rigorous evaluation. Each piece is subject to specific product standards that uphold strict Fai Po quality standards.